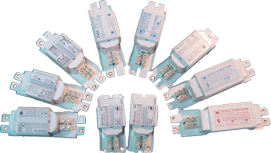

UV curing offer highes quality ballast and capacitor,Magnetic UV ballast transformers are used to initiate and control the arc in mercury and metal additive curing lamps. Ballast provide an instantaneous high voltage to strike the elements within a mercury vapor lamp, creating a plasma that once initiated, is susstained by the ballast. Total wattages upto 50 kilowatts can be designed. Our constant wattage ballast consists of a transformer, capacitors and ignitor. The advantage of a constant wattage ballast is that it allows for wide variations in input voltage to affect output wattage by only a few percent. These range can be customize to meet your applications requirements. Typical designs have an output varication of only +/-3% with an input voltage constant wattage is accomplished by a resonant tank circuit in which lamp winding is in a controlled magnetic saturation with ac capacitors, such that voltage swings on the input side have a very small impact on lamp current.

An interesting feturer is that these current limiting capacitors can be switched in and of the circuit to provide various lamp power levels.An arc–discharge lamp initially starts as a non–conductive gas between two electrodes. The ballast must supply adequate voltage to initiate an arc between the electrodes. This voltage is supplied by a transformer section within the ballast, and is sometimes supplemented by an ignitor that supplies additional high voltage pulses timed with the peak of the transformer voltage. Once the gas in the lamp’s arc tube becomes ionized, the electrical resistance drops very low. The ballast must then limit the current to protect the electrodes from overheating. As the current flows through the ionized arc stream, the gas is heated and pressure builds within the arc tube. This pressure in turn causes resistance to develop in the arc stream. The increased resistance leads to further heating and pressure. The ballast must control the current to make the lamp operate in a stable manner at its proper wattage. Without current regulation of the ballast, the pressure would increase until the voltage supplied to the lamp is incapable of passing between the electrodes. The ionization would cease and the lamp extinguish. Improper ballasting will cause lamps to operate outside their optimum performance envelope. The result is that lamps won’t operate at their correct wattage, won’t produce the correct light output, and will experience shortened life. The ballast must therefore supply proper voltage to start and maintain the arc, and must control current to regulate the lamp at its correct operating wattage.

UV ballasts are avaliable in 50,60 or combination of 50/50 hz. Typically, input power factor is better than ninety(90%) percent at nominal input voltage. Ballasts are constucted using silicon grain oriented steel, ul rated copper wire, ul class h insulation system and impregnated with a unique epoxy vanish for maximum thermal transfer.

Metal Halide Ballasts | High Pressure Sodium Ballasts | Fluorescent ballasts | Gear Tray

Links: Porcelain lamp socket | Mercury Vapor Ballast | Light bulb socket

Xml Copyright: @2012-2020 James Lighting Electronic Co.,Ltd